The Universal breathing buffer box G3B

Ageing of the transformer’s insulation system is accelerated by oxygen dissolved in oil. With open-type transformers oxygen consumed is replenished from the atmosphere. This longtime effect has negative implications.

The breathing buffer box (G3B) inserted in the transformer’s breathing line upstream of the dessicant layer is deemed to solve this problem. This ensures hermetical sealing of the transformer.

Extension of the life time of open-type transformers

(Subsequent) hermetic sealing of transformers using the G3B breathing buffer box

Oxygen in oil causes premature aging of the insulation system and is today one of the major causes of reduced transformer life. Transformers with air sealing ensure a longer life of the fixed insulation, and the oil quality is maintained for a longer period of time so that they have a longer life than opentype transformers. Therefore, the demand for hermetic sealing of new transformers as well as for subsequent hermetic sealing of existing open-type transformers is increasing.

Disadvantages of hydro-type compensators

New transformers with conservator are provided with hydro-type compensator whose operation is, however, often associated with the following disadvantages:

- High initial costs

- Intensive maintenance: The membrane ages faster than the transformer; some operators

say that it has to be replaced at least three times during the expected transformer life - The replacement costs significantly exceed the initial costs

- No moisture transport to outside

- Degassed oil affects the gas accumulation function of the Buchholz relay

- In practice, monitoring of the hermetic sealing often proves to be difficult

Advantages of the breathing buffer box G3B

The breathing buffer box (G3B), as an alternative, provides the following advantages:

- Low-cost and significant extension of the life of transformers

- Proven delayed aging processes of solid insulation of the transformer

- No interference with the oil system of the transformer during installation

- Monitoring function of the Buchholz relay is maintained

- Easy access near floor level (therefore it is particularly suitable for small transformers in areas which are otherwise not easily accessible)

- After replacement of the transformer, the G3B unit can still be used for other transformers

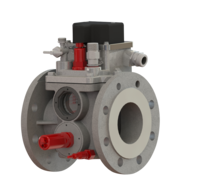

Construction and function of the G3B unit

The G3B unit consists of a cylindrical box integrated in the breathing line of the transformer directly upstream of the desiccant. Optionally a nitrogen gas cylinder can be integrated. The box is provided with a bottomless inner cylinder and is partly filled with oil as a service medium for pressure variation and as a diffusion lock. Floating aluminium disks separate the oil from the ambient air so that the low-oxygen air in the gas chamber of the conservator (grey) is separated from dry ambient air (white) as far as possible.

The G3B unit provides two natural end positions for the oil level differences which serve to compensate temperature variations up to 30°C in the oil tank.

If the atmospheric pressure in the conservator is exceeded by 40 mbar (maximum oil level in the inner cylinder), gas is released into the atmosphere. If pressure falls below the atmospheric pressure by 20 mbar (minimum oil level in the inner cylinder), either dry ambient air (subsequent natural hermetic sealing) or nitrogen from the pressurised gas cylinder (subsequent N2-aided hermetic sealing) is supplied.

There are two options for (subsequent) hermetic sealing using G3B units:

Natural (G3B): As the active part starts to age, oxygen consumed is continually replaced by air. Finally, the oil has a very low oxygen concentration.

N2 aided (G3B/N2): Oxygen consumed is replaced by nitrogen. Additionally, N2 is added during cooling down and resaturation. This procedure allows more comprehensive and effective subsequent hermetic sealing of transformers. Finally, the oil has a low oxygen concentration, however, this state is reached significantly faster.

The G3B diffusion barrier does not only prevent that air gets into the service area, but also that fault gases (H2, CO) which are only slightly soluble in oil leave that area what improves reliability of the diagnosis of service conditions.

Please contact us! We are glad to advise you and help with your selection.